Don’t have time to read the whole thing? You’ve come to the right place for the best brush cutter reviews.

[table id=8 /]

Our Top 3 Best Brush Cutters

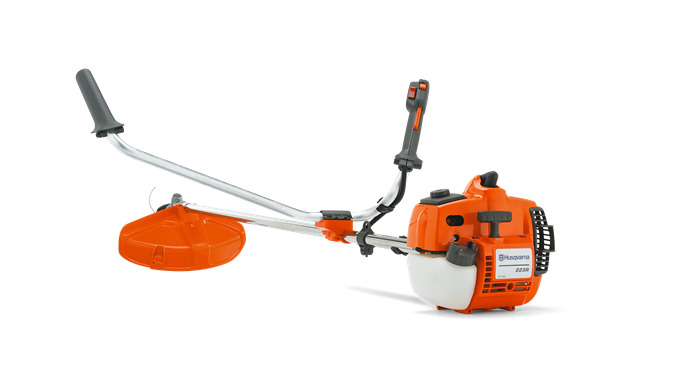

- Husqvarna 223R – It has enough power for a most applications. We like the straight shaft and bicycle bars. Husqvarna makes great chainsaws, and they don’t seem to slack in the brush cutter department either. It’s a little pricey, but we’ll take it over the equivalent dealer only Stihl and RedMax.

- The Blue Max is a bit of a beast with a good Horse Power/Dollar ratio. Bicycle bar handles and a lot of motor for the money. Blue Max seems to be new to the brush cutter game, so the jury’s still out on long term reliability.

- Husqvarana 223L – Like the 223R, the 223L is essentially the same but has a loop handle instead making it a little more taxing for long jobs.

Keep reading to understand out thought process.

Introduction

Is this your lawn?

Where do you even start! I can tell you from experience what is not going to work.

- Running your lawn mower over this mess

- Using your weedwacker

What you need is a brush cutter! The best brushcutters! Think of a weed eater (or string trimmer of you want to be politically correct about it) and the brush cutter is the bigger and beefier brother.

String Trimmer Head versus Brush Cutter Head

The string trimmer is a powered tool used to trim the edges of your lawn. It goes where no lawnmower can go. It is great for doing the fine detail work that you can’t do with lawn mower. What happens when the vegetation is too thick or too tough for a string cutter? You call in the Marines of lawn care, the brush cutter.

[table id=7 /]

Do I Need a Brush Cutter?

As you look at the Garden of Steven, you wonder how else you can handle it. Options?

[table id=6 /]

The brush cutter is best used in a situation where you have

- Overgrown foliage with thick grasses, tall grasses, “woody” grasses, nettles, brambles, underbrush, and saplings

- Fence lines that can’t be reached with mowers and tractors and have hearty foilage

- Areas that on a grade or hill that require a person to do the work, and can’t be safely done by tractor or mower

Can’t I just use a String Trimmer?

You can always try. You will probably run out of power before you clear what you need to clear, and you will not have the power to cut through dense undergrowth. A better question is do YOU need to BUY a brush cutter. When you look at the savage land slowly taking over your property, you have a few options

- Hire a contractor – Getting someone else to do it

- Renting one and doing it yourself

- Buying a unit.

If this is an out of the ordinary/one time situation like your parents letting the backyard get out of control, I actually recommend you have your local lawn care professional do the initial work. When the rough cut has been handled, then you may need a brush cutter for maintenance and touch ups. If money is tight, then renting is your next best option. Your local big box hardware store may have them in their rental section, and your specialty lawn care provider will have some for rent. But if property maintenance on this level is going to be an ongoing concern, buying is your best option.

What do I look for in a brush cutter?

The feature

- Power – Strong enough to do the job,

- Ease of use – Easy to start, easy to use, and easy to care for

- Reliable – Will it last?

- Price – Does it do the job for the money?

Let’s start with power. Brush Cutters are powered in 1 of 4 ways, 1) by wire, 2) by battery, 3) by 4 stroke gasoline engine or 4) by 2 stroke gasoline engines. I recommend sticking to 2 stroke engines.

Here’s a handy dandy comparison chart

[table id=5 /]

For now, the electric brush cutters are considerably less powerful. What they lack in power they make up for in being light weight, operating quietly, and can be maneuvered or oriented in any direction. However, if you’re not trying to clear brush in a national forest, just got an acre or two, you might try this electric brush cutter.

The gasoline/petrol brush cutters are more powerful, but they are heavier, louder, and require you to have access to gasoline.

If you stick with my general recommendation, you’re going to pay more for your gas powered unit, but you’ll get the job done.

Two Stroke Engines v. Four Stroke Engines

A little history lesson first.

This is some animation for a four stroke engine.

This is some animation for a two stroke engine.

For our purposes, 2 stroke engines tend to be more powerful than 4 stroke engines. And since they have less moving parts, 2 stroke engines tend to be more reliable.

In choosing between a two-stroke or a four-stroke, four-stroke engines tend to be better on fuel, quieter, and less emissions. At the time of this writing, four stroke engines are more expensive. Two-stroke engines are generally more powerful than four0stroke engines thus tw0-stroke engines are worse on fuel economy, have worse emissions. What they lose in fuel economy and emissions, they make up for in price and more reliability because they have less moving parts.

And speaking of less moving parts, the 4 stroke has a separate oil pan to lubricate the engine. Many lawnmowers are 2 stroke engines and generally cut grass flat on the ground. A brush cutter or a string trimmer often has to be tilted and held at odd angles in order to do its job. That tilt can result in oil moving out of where it needs to be, exposing the engine to greater wear or even damage.

Q. Do I need anything special when I gas up my brush cutter?

A. Two stroke engines, because they have no oil pump, require require gasoline plus some oil. If you run a two stroke engine without adding oil, the engine will seize up and you are going to be in for an expensive repair.

Q. Do I need special gasoline or will any gasoline work?

A. For most of these brush cutters the manual specifies the use premium gasoline with no ethanol in addition to the fuel oil. My research has uncovered that many lawn care professionals will use whatever gas is available.

Other Features

Now that you’ve rightly decided on a gasoline two-stroke power plant, what other features are useful in a brush cutter?

Shaft

A solid steel shaft to drive the cutting head is necessary. Brush cutters come in straight shaft and bent shaft configurations. Bent shafts allow you to get closer what you’re cutting and are sometimes a good choice if you’re doing a lot of detail work. However the additional precision comes at a cost. To bend the shaft, manufacturers put a mechanical linkage between the gas engine and the cutting head. This linkage necessarily is not as powerful as a straight shaft, and because of the typical use (and abuse!) for a brush cutter the bent shaft often has more mechanical problems.

2 Stroke Engine + Solid Steel Shaft – what next?

Glad you asked. The recent trend in the power tools industry is to sell you a strong motor with good internals and good drive shaft to do lots of different tasks. Your drill can become a ratchet or an electric screw driver. Your rotary tool can cut, sand, and gouge. This trend of multi-use tools is welcome, but sometimes you need a dedicated tool.

Quick Change Heads

This trend is now entering the brush cutter market. There are manufacturers offering “quick change”. Avoid at all costs. The standard use for a brush cutter tends to be greater than current levels of engineering. So if you want to change the cutting element on your unit from a tri-blade to a quad blade or to a many toothed saw blade – pick a unit that requires you to to break out your hand tools and get intimate with your brush cutter.

That wraps up the performance and reliability portion of the guide. Bottom line, we’re looking for a gasoline powered brush cutter with a 2 stroke engine that drives a solid steel shaft into the cutting head that is not a quick change head.

2 Stroke Engine + Solid Steel Shaft + Slow Change

Ease of Use

Power

How much power do I really need for my routine tasks?

Power, such a tricky concept. More than just engine displacement, fuel tank capacity, or horse power ratings, power is not just a raw number, but it is how much work you can do given the task at hand. The rule of thumb with power tools is to get something slightly more powerful than you need, but how much power do you need? How much power is too much? How much power is dangerous?

A professional clearing underbrush in a forest to prevent wildfires needs something that is very powerful because they’re likely to encounter tough saplings on a routine basis. Too little power and the job takes too long. That kind of power might not be appropriate for keeping a fence line clear. You may spend too much up front, too much on fuel, and then dreading having to take the monster out. And you never know what accident might happen because the cutting edge goes too quickly through the brush.

We’ll leave the power question for the end.

Handles and Handling

One handed or two handed? You can buy brush-cutters in two designs.

The one handed loop design (right) And the two handed design (left). The two handed design is also known as bull horns, bulbar, bul-bar, tubular, bike handles. The handles are typically offset and designed for use with a harness. As of this writing, I do not know if they have right handed folks or left handed folks.

The one handed design allows for some ease of use, but given the general power of a gas powered brush-cutter and safety concerns you want to use both hands. Also for using a scythe-style motion for clearing land, two hands make it very easy to get a lot of work done quickly.

In terms of handling, if you have a big project a harness plus two handles is the best option

Vibration

A quality brush cutter unit will be engineered to reduce vibration. When it’s idling and not working, the anti-vibration works well. When the brush cutter actually “bites” into a bushes, nettles, and trees, that’s when you’ll notice how good the brush cutter is.

Some brush cutters are designed to be used at full speed, and they may vibrate at lower speeds.

The amount of vibration seems to be different for every machine. Some users will

So with respect to ease of use – 2 handles and anti-vibration technology. Power is the open question.

So what do I recommend. Based on my overall guidance

- 2 Stroke Engine

- solid steel shaft

- 2 handles

- anti-vibration/dampening technology

Power Revisited

If you have a strong engine with a strong linkage, controlled by 2 handles, and the vibration is mitigated by technology, power is your last concern. For heavy foliage many experts recommend a displacement of greater than 35cc and a hp that is 2.0 or greater. For moderate underbrush, a displacement in the mid 20’s and HP greater than 1.2 hp is ideal.

So we had to look at a good # of brush cutters to make our determinations.

Best Brush Cutter Brand

This is a really tough question. If you take it back to the 80’s (when I was a teenager mowing lawns), most of the top brands were made here in the States for US conditions. Names like Echo, Redmax, Stihl, all come to mind. Tanaka and Honda had offerings from Japan, and Stihl from Germany and Husqvarna from Sweden all offered options. Now, we’re in a global economy and different areas have different requirements. Lots of US made options have expanded. This isn’t necessarily a bad thing, but when the factory was in Ohio, new parts weren’t coming across the ocean.

At the commercial level, operations that will pay a lot for the brush cutter and also have dedicated people no staff to keep the machines in tip top shape. For them Stihl is the name to be reckoned with. You have to go to a dealer to buy, and usually to service. None of which come cheap. If you’re making money with the equipment, it’s the cost of doing business. However, most of us don’t run lawn care companies or forestry service organizations.

Brush Cutters Reviews

Troy-Bilt Brush Cutter TB 42

Troy Bilt TB 575 Review

Tanaka TCG31EBSP Brush Cutter Review

Husqvarna 223R Review

Husky 223L Review

Husqvarna 128 LD Review

Blue Max Brush Cutter 52623 Review

Tanaka Brush Cutter TCG31EBSP Review

Here are the recommendations.

For 4 Stroke – We like the TB 575 from Troy Bilt

Our full review is here.

The TB 575 does not have a whole lot of competition for a 4 Cycle. With Honda out of the game, the only other easily found option is the Poulan Pro.

For the 2 Stroke, here are our top 3 again

3. The Loop Handle 223L from Husqvarna. Our full review is here. You can find it on Amazon here.

2. The Blue Max 52363 from Blue Max. We covered this brush cutter earlier this year. Amazon has it here

So what is the best brush cutter?

1. Our #1 pick for 2016 is the Bicycle Bar Handle 223R from Husqvarna. Full review is here.

Honorable mention is the TCG#31EBSP from Japanese manufacturer Tanaka.

If you’ve ever had to deal with a large amount of brush that needs to be cleared you would know that a simple line trimmer while highly efficient at cutting grass and trimming in those hard to reach places is not cut out for denser vegetation, or anything thicker than a quarter inch. For jobs where you are cutting denser vegetation you need a brush saw, or clearing saw. Like the trimmer the brush saw has many different names and applications, some people call it a regular trimmer and others prefer to call it a clearing saw. You can use a brush saw to hedge, prune and clear thick grass that would bog down a string trimmer as well as thick vegetation that even a mower cannot handle.

With brush cutters you have the option of either gas or electric, the downside of electric is that it is limited by the length of the cord and more suited for consumer use, whereas the gas brush cutter is much more powerful, and more versatile, which is ideal because you’re typically only going to need a brush cutter in more remote areas that aren’t well maintained. Most trimmers can be turned into brush cutters, you simply take off the trimmer head and attach a brush blade to the trimmer. If you’re going to turn a regular trimmer into a brush cutter there’s a few things you need to be aware of.

1.Does your trimmer have enough power to handle a brush blade

2.What handle does your trimmer have

For a trimmer to effectively handle attaching a brush blade you must make sure the trimmer has at least a 20cc engine. Anything less than 20cc won’t be able to spin the blade at high enough RPM’s.

Most trimmers have a loop style handle which is inadequate for larger clearing jobs.

![[Image: stihl-trimmer-fs-55-r-90-r-km-55-90-loop...e6e3c8.jpg]](http://d2ydh70d4b5xgv.cloudfront.net/images/d/5/stihl-trimmer-fs-55-r-90-r-km-55-90-loop-handle-weed-eater-40563dde90936f4211066d305fe6e3c8.jpg)

The loop style of handle is great for precision tasks and where control is paramount, however brush cutting typically doesn’t require precision, brush cutting requires more force to chop through vegetation. This is why many brush cutters have handles that look like they are from a bicycle.

![[Image: fs55-2.jpg]](https://www.worldofpower.co.uk/media/catalog/product/cache/1/image/1200x/040ec09b1e35df139433887a97daa66f/f/s/fs55-2.jpg)

These handles provide the operator with more movability as well as being able to apply more force to cut through vegetation, they are also more comfortable for longer jobs and many times you can add straps or a harness to them to further increase comfort.

![[Image: CorpFull_1.png]](https://www.stihlusa.com/WebContent/Images/Product/956/CorpFull_1.png)

This is the ideal set up for brush cutting, allowing optimal comfort and power for those long jobs where a regular loop handle won’t suffice.

Many people think that attaching a circular saw blade to a trimmer effectively turns it into a brush cutter and saves them the extra thirty dollars on a brush blade. While this seems like a good idea.

It’s not.

The problem lies with the RPMs a brush cutter produces, a brush cutter running on full throttle can be within the range of 7000-10000 RPM’s whereas a circular saw runs at about 3540 RPM’s. This is more than double the RPM’s a circular saw blade is designed for, making the blade unstable and any form of impact whether it be a rock, or a hardwood tree will cause the blade to shatter, sending pieces of shrapnel in every direction.

The good news is brush blades aren’t very expensive and if you buy the right ones as well as sharpen them often you will get a lot of use out of a single blade. But before you buy a blade, there’s a few important details you should know.

Diameter of blade

Arbor Hole Size

Amount of teeth

Carbide Steel or Steel

Guard or no guard

The first and most important factor when choosing a blade is the diameter. The wider the blade, the more powerful of a machine you need to have in order to cut through the vegetation. Blades come in three diameters, 8”, 9” and 10”. The larger the blade the more power your machine needs to keep it at high enough RPM’s. If your blade is not spinning fast enough, not only will it make the job more of a hassle than it should be, you also introduce kick back meaning the blade will kick away from thicker vegetation because it cannot cut it. This is a problem because essentially you are losing control of the brush blade, and its hard on the body when you have to deal with constant kick.

To attach a blade to your machine you need to know the size of the arbor hole

Most brands have 20mm arbor holes but some use 20.45mm arbor holes. STIHL is known to use the slightly larger 20.45mm hole. It is best to double check the size before buying a blade.

The next thing you want to be aware of is the amount of teeth on the saw, this is important because the more teeth you have on the blade the more cutting power you have. Cutting power and teeth are directly proportional however, there are some blades don’t have any teeth on them at all just blades.

![[Image: brushknife.png?preset=Product.ProductDetails]](https://www.stihlusa.com/WebContent/Images/Product/794/brushknife.png?preset=Product.ProductDetails)

The brush blades that have no teeth are your most basic blade, only designed for dense grass and very light vegetation, these blades dull quickly making them unsuitable for heavy or even medium duty work. There isn’t much of a reason to buy these, a blade with teeth on it will cut just as well and is more versatile.

Then you have the blade with 30-40 teeth. These blades are designed to cut through heavy stock brush, thick brush and brambles but due to the low amount of teeth, you cannot hedge or prune with this blade. These are best suited for medium use, where you will not be cutting anything too thick in which case you would need a blade with 80-120 teeth.

The 80-120 toothed blade is your most versatile and best value of the different types of blades, these blades can take care of any brush you throw at them, they can prune, hedge and stay sharpest the longest of the different types. The only issue is once you get into 100 toothed blades and 120 toothed blades the diameter changes from 8” to 9” which as I stated above, can cause issues with your machine struggling to keep up with the RPM’s necessary.

The final thing you want to be aware of when choosing your blade is the type of steel the teeth are made out of, it can either be steel or carbide steel.

Regular steel costs less, is more abundant at your local big box store and is great for light use or if you don’t have the need for a brush cutter often. Regular steel is also easy to sharpen. Carbide steel is longer lasting, a little bit more expensive and harder to sharpen, carbide steel is far superior to a regular steel blade while only costing a little bit more. You should always buy carbide blades, there’s no reason to buy steel blades even if you only plan to use them once. A blade with 30 teeth on it that are tipped with carbide steel is far superior to a regular steel blade with 100 teeth, despite having 70 teeth less than the carbide version.

Depending on the design of your trimmer, you may have to take the guard off in order to fit the brush blade, this can cause safety concerns because you will have nothing to protect you from debris. The plus side to remove the guard is you will deal with less clogs and have an easier time clearing. I personally cut with the blade off but it’s your discretion, if you want to keep the guard on your brush cutter or trimmer then it is best to do a quick measurement before purchasing anything.

There’s many, many different designs for Brush blades and many of which I haven’t mentioned. There’s a simple reason for this, most of them are not safe. In the UK during 2010 there was a fatal incident with a flail type of blade

![[Image: Chain-Flail-Type-Brush-Cutter-Blade-600x298.jpg]](http://brushdestructor.com/wp-content/uploads/2015/06/Chain-Flail-Type-Brush-Cutter-Blade-600x298.jpg)

The one in question didn’t even have a blade attached to it, but rather chain to act as a form of crusher. This sounds like a good idea but when that chain is spinning at 7000 RPM’s and it grabs a rock it’s going to send it light speed toward you and I hope you’re wearing a teflon vest for when that sucker hits you. In EU and Australia these types of cutters are banned.

Which is why it is wise to stick with the circular type of blade, it’s the safest blade to use. There is however one flail blade I will recommend, it’s expensive but if you want something that’s going to last a long time and has superior cutting power to anything else on the market then this blade will be your best option.

![[Image: Brushcutter-Blades-Extra-Heavy-Duty-Brus...-blade.jpg]](http://brushdestructor.com/wp-content/uploads/2013/06/Brushcutter-Blades-Extra-Heavy-Duty-BrushDestructor-blade.jpg)

The BrushDestructor blades are your absolute best option, even though they are a flail type of blade they have been tested and many professionals use this brand. The great thing about them is they are very versatile, able to handle any brush, weed, bramble, or job you throw at it them. You do not have to deal with switching blades depending on the type vegetation you are cutting. The blades are easy to sharpen and tangle free, which means more time cutting, and less time idle. The downside to these blades is that they are expensive, mainly because each order is done by hand which drives the price up but also means that quality control and customer service will be exceptional. They are made in a little shop out of Australia and the company has been supplying landscapers the best blade on the market for many years now. If you run a professional business and want something that’s going to last a long time, and provide you with a superior cut these blades are the best option. You can find them here.

The next blade that I’ve chosen is the STIHL Circular Saw Blade – Scratcher Tooth.

![[Image: 31iEcduDG5L._SX300_.jpg]](https://images-na.ssl-images-amazon.com/images/I/31iEcduDG5L._SX300_.jpg)

This blade comes in both 20mm and 20.45mm arbor hole sizes and are about the best blade on the market and will handle anything you throw at it, able to cut through brambles, thick weeds, dense grass and even prune and hedge for you, this blade does it all. I’ve personally used this blade when I worked at a high end private golf course and I had no issues with it clogging or not being able to handle the job. It made spending a week on a brush cutter an enjoyable experience.

There’s one thing to be careful of when you purchase this blade, and that is to make sure it uses Swedish steel and not the Japanese counterpart. Japanese steel is much softer and therefore dulls quicker than Swedish steel, you should be able to check on the back of the package to see where the steel comes from.

You can buy the blade that uses Swedish steel here.

![[Image: 41qM-57eajL._SY450_.jpg]](https://images-na.ssl-images-amazon.com/images/I/41qM-57eajL._SY450_.jpg)

The third blade I’m going to recommend is the 8” Renegade Brush Blade, this blade is designed for multi use which means it can cut brambles, thick brush and weeds with ease as well as hedging and pruning. I choose this blade because it’s a slightly different design than the STIHL blade, which means the cut will be slightly different as well, along with the feel. STIHL blades tend to be a little more heavier than aftermarket blades, the STIHL blade is a heavier blade whereas the Renegade blade is lighter. It comes down to personal preference, both the Renegade and STIHL blade will do the same job, in the same amount of time, and cost about the same, it’s just a different feel. Renegade blades tend to be a bit easier to sharpen as well, according to professionals. You can buy them on Amazon here.

The three blades I have chosen are the best when it comes to versatility, price, cutting power and are used by professionals and consumers alike. Brush blades can be more confusing than trimmer line, there’s so many different designs out there and most of them are rubbish. Knowing what blades are the best can make the difference between spending two hours clearing an area and four hours because the blade you have is inadequate for the job. Brush cutting isn’t supposed to be a chore, and with the blades I recommended I can assure you that you will learn to enjoy clearing large areas of vegetation, hassle free. Happy cutting.

![[Image: promoting-safety-in-schools-preview.jpg]](http://lawnchat.com/wp-content/uploads/2009/04/promoting-safety-in-schools-preview.jpg)

![[Image: image_57153.jpg]](http://workingperson.com/media/catalog/product/cache/1/image/400x/9df78eab33525d08d6e5fb8d27136e95/i/m/image_57153.jpg)

![[Image: ap69018_ap66104.jpg]](http://www.earplugsrus.com/media/catalog/product/cache/1/image/9df78eab33525d08d6e5fb8d27136e95/a/p/ap69018_ap66104.jpg)

![[Image: 91oxcNBeZPL._SL1500_.jpg]](https://images-na.ssl-images-amazon.com/images/I/91oxcNBeZPL._SL1500_.jpg)

![[Image: 1746366_2000x2000.jpg]](http://www.northerntool.com/images/product/2000x2000/174/1746366_2000x2000.jpg)

![[Image: 41StdCoScJL.01_SL500_.jpg]](http://ecx.images-amazon.com/images/I/41StdCoScJL.01_SL500_.jpg)

![[Image: 81DVHU35IqL._UL1500_.jpg]](https://images-na.ssl-images-amazon.com/images/I/81DVHU35IqL._UL1500_.jpg)

![[Image: spf-50.jpg]](http://underthesunskincare.com/wp-content/uploads/2016/02/spf-50.jpg)

![[Image: r4a028867_rrd_productcallout_304x218.jpg]](https://www.deere.com/common/media/images/products/equipment/Z_trak_mowers/r4a028867_rrd_productcallout_304x218.jpg)

![[Image: home-depot-2.jpg]](https://www.observeit.com/sites/default/files/content_images/blog_images/home-depot-2.jpg)

![[Image: lawnmow_main1.png]](http://blackdiamondlandscapes.com/wp-content/uploads/2012/08/lawnmow_main1.png)

![[Image: mower414.jpg?resize=580:435]](https://media.healthday.com/Images/icimages/mower414.jpg?resize=580:435)

![[Image: 78a9a710053529.560deb952e6c7.png]](https://mir-s3-cdn-cf.behance.net/project_modules/disp/78a9a710053529.560deb952e6c7.png)